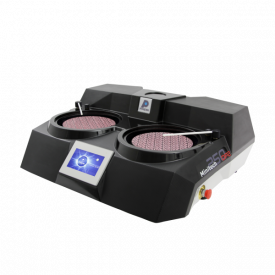

MINITECH 300 SP1

MINITECH 300 SP1 is a manual polishing machines equipped with a Ø 250 to 300 mm platen. It has the most advanced technologies. Thanks to a motor power from 750W to 1500W, the entire PRESI experience is condensed in this most complete range

on the market. User-friendly, reliable and robust, MINITECH provides a simple answer to all needs. With its affirmed style and edged lines, this new range is distinguished by its new design with an easily recognizable sleek and refined carbon look.

Semi-automatic Hardness tester HZ30-2

Semi-automatic hardness tester. Optical quality, reliability and precision. The HZ30-2 hardness tester is instantly recognizable. 100% made in France, its original design along with its robustness and highly technical capacities make it an essential work tool. High rigidity of the chassis for a perfect load application.

– Load range : 100gf-30kgf

– Turret: : up to 4 lenses, 2 indenters, 1 touch sensor

– Indenter type : Vickers or Knoop

– 1 load cell

– Nikon objectives for a magnification up to 2000x

– Silent operation

– Major vertical extension: allows a large work space

– 2 LED lighting system: for micro and macroscopy use

– Fixed or manual stage

Key word: hardness

Automatic Hardness tester HZ2-4

Automatic hardness tester. Optical quality, reliability and precision. The HZ2-4 hardness tester is instantly recognizable. 100% made in France, its original design along with its robustness and highly technical capacities make it an essential work tool. High rigidity of the chassis for a perfect load application.

- Load range : 5gf-2kgf

- Turret: : up to 4 lenses, 2 indenters, 1 touch sensor

- Indenter type : Vickers or Knoop

- 1 load cell

- Nikon objectives for a magnification up to 2000x

- Ergonomic joystick with customizable sensitivity

- Silent operation

- Major vertical extension: allows a large work space

- 2 LED lighting system: for micro and macroscopy use

- Standard or marble motorized stage

Key word: hardness

MECATOME T265

Robust, the MECATOME T265 accepts cutting discs of Ø250 & Ø300mm. Its rotation speeds ranged from 1300 to 4000 RPM allow the use of metallic blades as resinoids. Its L-shaped table allows quick clamping of parts either horizontally or vertically.

Options and accessories:

- Magnetic filter (ref. 51271)

- Quick-release nut - Tool-less cut-off wheel change (ref. 51272)

- SUCTION AND EXTRACTION - Mist extraction with fluid recovery (ref. 51273)

- Base cabinet for manual cutting machine (small model) (ref. 51275)

- Left quick clamping vice (ref. 51280)

- Right quick clamping vice (ref. 51281)

- Stainless steel v-type moving jaw for clamping vice 45mm height (ref. 51282)

- Special fragile samples «delrin» thermoplastic moving jaw for clamping vice 45mm height (ref. 51283)

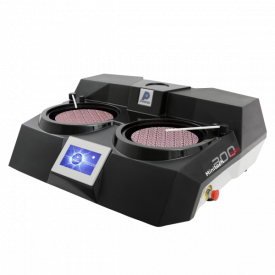

MINITECH 250 DP1

The MINITECH 250 DP1 is a manual polishing machine equipped with two platens Ø 200 to 250 mm and one motor. It has the most advanced technologies. Thanks to a motor power from 750W to 1500W, the entire PRESI experience is condensed in this most complete range on the market. User-friendly, reliable and robust, MINITECH provides a simple answer to all needs. With its affirmed style and edged lines, this new range is distinguished by its new design with an easily recognizable sleek and refined carbon look.

Automatic Hardness tester HZ10-4

Automatic hardness tester. Optical quality, reliability and precision. The HZ10-4 hardness tester is instantly recognizable. 100% made in France, its original design along with its robustness and highly technical capacities make it an essential work tool. High rigidity of the chassis for a perfect load application.

- Load range : 10gf-10kgf

- Turret: : up to 4 lenses, 2 indenters, 1 touch sensor

- Indenter type : Vickers or Knoop

- 1 load cell

- Nikon objectives for a magnification up to 2000x

- Ergonomic joystick with customizable sensitivity

- Silent operation

- Major vertical extension: allows a large work space

- 2 LED lighting system: for micro and macroscopy use

- Standard or marble motorized stage

Key word: hardness

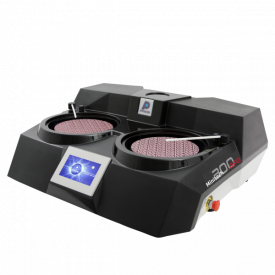

MINITECH 250 DP2

The MINITECH 250 DP2 is a manual polishing machine equipped with two platens Ø 200 to 250 mm and two motors. It has the most advanced technologies. Thanks to a motor power from 750W to 1500W, the entire PRESI experience is condensed in this most complete range on the market. User-friendly, reliable and robust, MINITECH provides a simple answer to all needs. With its affirmed style and edged lines, this new range is distinguished by its new design with an easily recognizable sleek and refined carbon look.

Automatic Hardness tester HZ30-4

Automatic hardness tester. Optical quality, reliability and precision. The HZ30-4 hardness tester is instantly recognizable. 100% made in France, its original design along with its robustness and highly technical capacities make it an essential work tool. High rigidity of the chassis for a perfect load application.

- Load range : 100gf-30kgf

- Turret: : up to 4 lenses, 2 indenters, 1 touch sensor

- Indenter type : Vickers or Knoop

- 1 load cell

- Nikon objectives for a magnification up to 2000x

- Ergonomic joystick with customizable sensitivity

- Silent operation

- Emajor vertical extension: allows a large work space

- 2 LED lighting system: for micro and macroscopy use

- Standard or marble motorized stage

Key word: hardness

MINITECH 300 DP1

The MINITECH 300 DP1 is a manual polishing machine equipped with two platens Ø 250 to 300 mm and one motor. It has the most advanced technologies. Thanks to a motor power from 750W to 1500W, the entire PRESI experience is condensed in this most complete range on the market. User-friendly, reliable and robust, MINITECH provides a simple answer to all needs. With its affirmed style and edged lines, this new range is distinguished by its new design with an easily recognizable sleek and refined carbon look.

Fully Automatic Hardness tester HZ50-4

Fully automatic hardness tester. Optical quality, reliability and precision. The HZ50-4 hardness tester is instantly recognizable. 100% made in France, its original design along with its robustness and highly technical capacities make it an essential work tool.

High rigidity of the chassis for a perfect load application.

- Load range : 5gf-65kgf

- Turret: : 4 lenses, 2 indenters, 1 touch sensor

- Indenter type : Vickers AND Knoop

- 2 load cells

- Nikon objectives for a magnification up to 2000x

- Ergonomic joystick with customizable sensitivity

- Silent operation

- Emajor vertical extension: allows a large work space

- 2 LED lighting system: for micro and macroscopy use

- Marble motorized stage

Key word: hardness

MINITECH 300 DP2

The MINITECH 300 DP2 is a manual polishing machine equipped with two platens Ø 250 to 300 mm and two motors. It has the most advanced technologies. Thanks to a motor power from 750W to 1500W, the entire PRESI experience is condensed in this most complete range on the market. User-friendly, reliable and robust, MINITECH provides a simple answer to all needs. With its affirmed style and edged lines, this new range is distinguished by its new design with an easily recognizable sleek and refined carbon look.

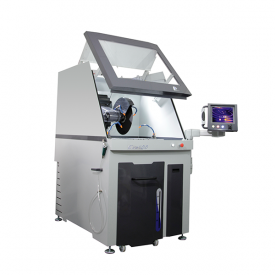

EVO 400

Large size cutting machine. Evo 400 Ref. 50400 / Evo 400+ Ref. 50430

The EVO 400 is a very spacious, large capacity machine. The height of the space under the grinding wheel measures 190mm. Its tables can bear the weight of parts over 200kg. This powerful machine, adapted for workshop use, combines ease of use with sturdiness. It has three cutting modes: assisted, automatic, programmable (ensures cut repeatability). Its ergonomic design, with a motorised hood and multilingual, coloured, touch screen simplifies the user-machine interface. Optional Extras:

• Positioning Laser.

• Manual transverse movement table (X axis) to assist with lateral adjustment of the simple, and enable parallel sectioning.

• Manual longitudinal movement table (Y axis) to increase cut capacity.