MEDICAL DEVICE QUALITY CONTROL

INTRODUCTION

A multitude of materials are used in the health field, for example in medical instruments and equipment (surgical tools, mobility devices, artificial limbs, etc.) and to compensate for functional deficiencies or injuries. All these materials come under the heading “biomaterials”.

Biomaterials, by definition, are materials used in a medical device intended to interact with biological systems to assess, treat, strengthen or replace a tissue, organ or body function.

Among the different biomaterials, two main categories can be distinguished:

LIVING (or natural) BIOMATERIALS

These are materials of biological origin. The principle is to create a natural base to accommodate the regrowth of a specific fabric allowing the replacement of the deficient function. Amongst these living biomaterials we find:

• Biological tissues (porcine valves, beef carotid, etc.).

• Grafts (xenografts, allografts and autografts).

• Coral, which is a natural porous ceramic. This porosity favours bone implantation. It is used in orthopaedic and maxillofacial surgery.

• Collagen, which is a natural protein of animal (skin) or human (placenta) origin whose applications are: cosmetology and cosmetic surgery, eye implants, tissue reconstructions, artificial skin and haemostatic dressings.

• Cellulose (dialysis membranes and cement for hip prostheses).

• Chitin extracted from crab shells (sutures, reconstructive surgery and artificial skin).

• Fucans extracted from seaweed (anti-coagulants).

INERT (or non-living) BIOMATERIALS

3 categories exist:

1. Metals and metal alloys

2. Ceramics (also called “bioceramics”)

3. Polymers

1. METALS AND METAL ALLOYS

• Stainless steels, which are steels (maximum 1% carbon) with at least 12% chromium content by mass. It is this chromium content that makes the steel stainless.

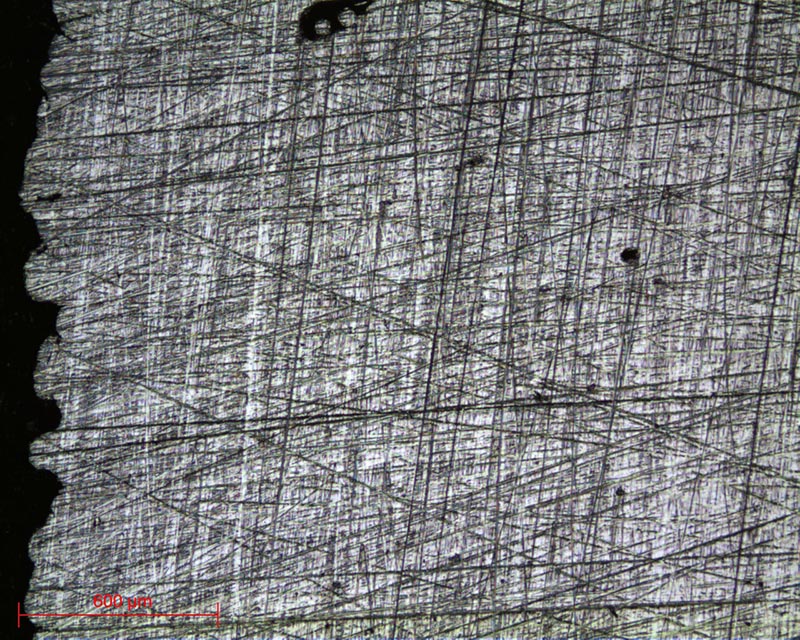

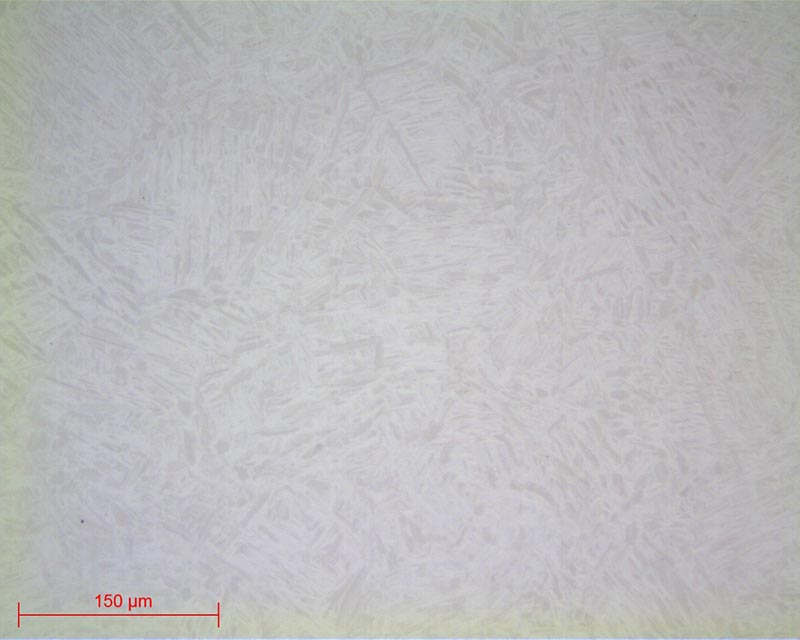

The types of stainless steel used in the biomedical industry are so-called “martensitic” stainless steels (magnetic and heat-treated) for surgical instruments and so-called “austenitic” stainless steels (non-magnetic and with a nickel content between 10 and 14%) for surgical implants.

Stainless steel is the most common metal used in the medical field, particularly austenitic stainless steel 316L (X2CrNiMo17-12-2).

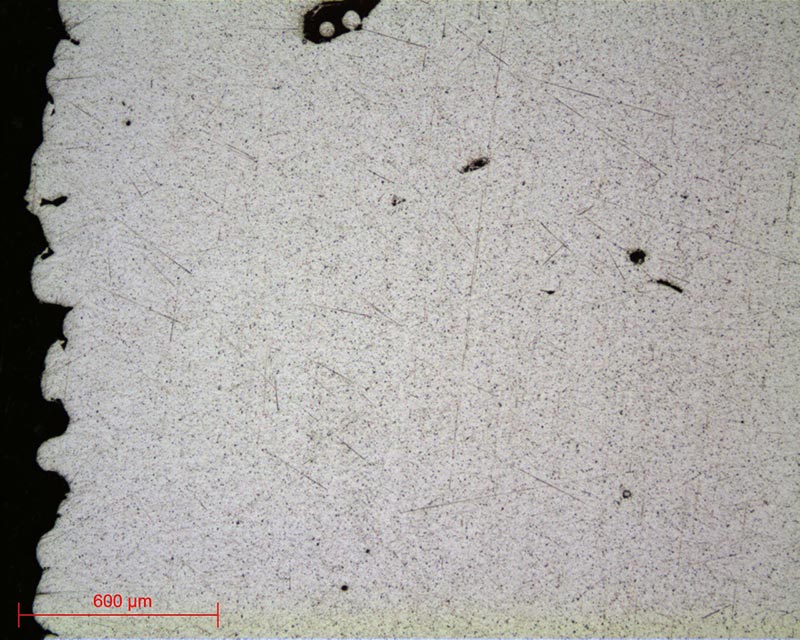

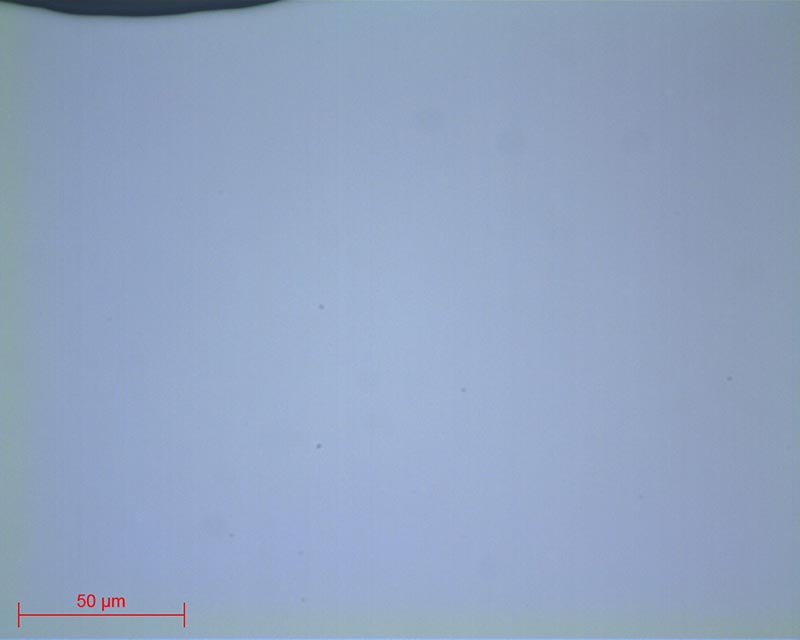

• Titanium and its alloys bring very beneficial characteristics in addition to biocompatibility. Their corrosion resistance is exceptional (higher than stainless steel) and they have better fatigue properties and better elasticity than cobalt-chromium alloys and stainless steels. The density of titanium is also a big factor, since its value is low for a metal (4.5 compared to about 8 for stainless steels).

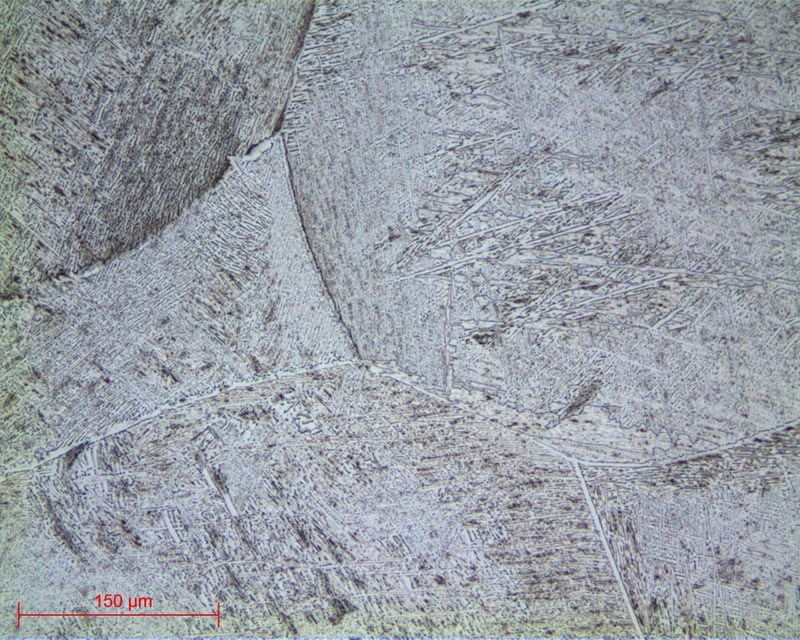

The applications of titanium in the medical field are very vast: implants, osteosynthesis, orthopaedics, prosthesis, etc… A very common grade of titanium is TA6V (TiAl6V4).

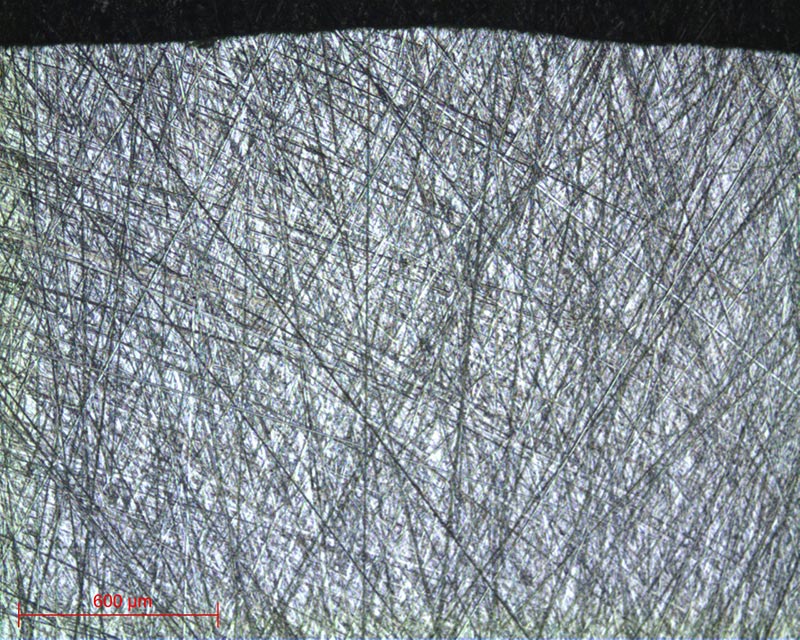

• Cobalt-chromium alloys (stellites), which are cobalt alloys with chromium as the main alloying element. They frequently have a high molybdenum content and a low carbon content (non-magnetic alloys).

The corrosion resistance of these alloys is excellent. Their mechanical properties are equally remarkable (high hardness, toughness and wear resistance), giving these alloys higher rigidity than stainless steels and titanium.

CoCr alloys are mainly used for hip, knee or rachis prostheses, for osteosynthesis and for dental prosthesis.

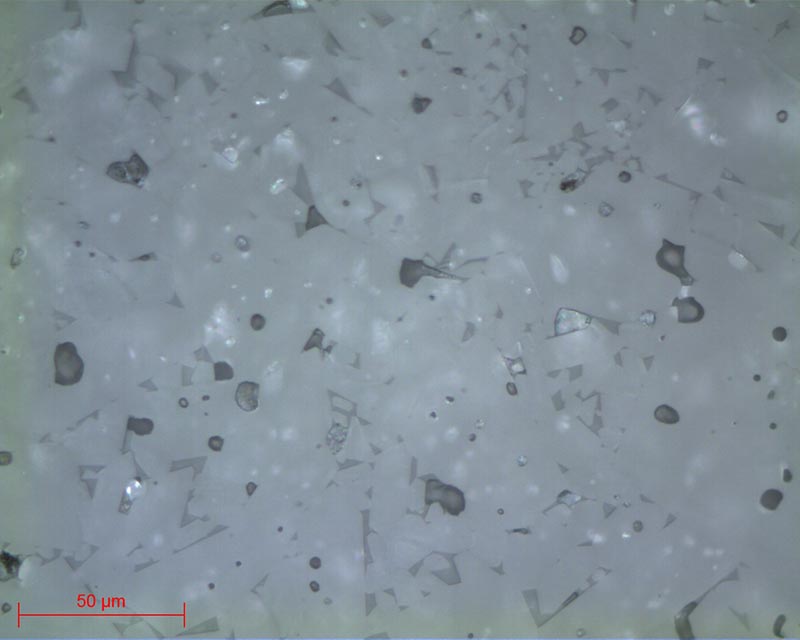

2. CERAMICS

• Alumina (Al2O3), is a pure, dense medical-grade bio-inert ceramic. It is mainly used for its good tribological properties, ageing and mechanical resistance. It is used for the tips of hip prosthesis and in dentistry (dental implants).

• Zirconia (ZrO2) has the same characteristics as alumina but with higher toughness, i.e. it has a better resistance to crack propagation.

• Hydroxyapatite (HAP) Ca10(PO4)6(OH)2 and tricalcium phosphate β (TCP) Ca3(PO4)2 are bioactive ceramics. These ceramics are porous, which makes them osteo-oconductive, i.e. they promote bone regrowth. They also have the advantage of being bioresorbable and are used for implants, orthopaedic surgery and dental fillings.

• Bioglass is a bioactive ceramic with a carbonated hydroxyapatite layer on its surface, which is chemically and structurally identical to the mineral phase of bone. A link can be made between the ceramic and bone, making osteoconduction and osteoproduction possible. Bioglasses are mainly composed of oxides, silicon (SiO2), sodium (Na2O), calcium (CaO) and phosphorus (P2O5).

3. POLYMERS

The following polymers stand out:

• Functional polymers are used as friction surfaces (in addition to metals and ceramics), as anchoring materials for prosthesis (allowing better convalescence) and in ophthalmology, neurosurgery, cardiovascular or plastic surgery (catheters, drains, syringes, prosthesis).

• Resorbable polymers make it possible to avoid further surgery. They must have sufficient mechanical properties to ensure their functions and then be resorbed afterwards. They are therefore used as surgical cements, bone fillers, diaphyseal obturators, suture threads, etc.

These biomaterials are developed and used in such a way that they are not rejected by the host’s organism, do not contain toxic elements and offer precise mechanical characteristics that cope with the various constraints exerted by the environment.

In other words, they must comply with very demanding specifications in terms of physico-chemical properties, shaping, service life and/or deterioration, porosities, implantation or injection, etc.

It is for these same reasons that a multitude of tests must be carried out, some of which require metallographic preparation.

METALLOGRAPHIC PREPARATION

• Standardisation of the geometry of the sample taken (if necessary), called “MOUNTING”.

• Improvement of the surface condition of this sample, called “POLISHING”.

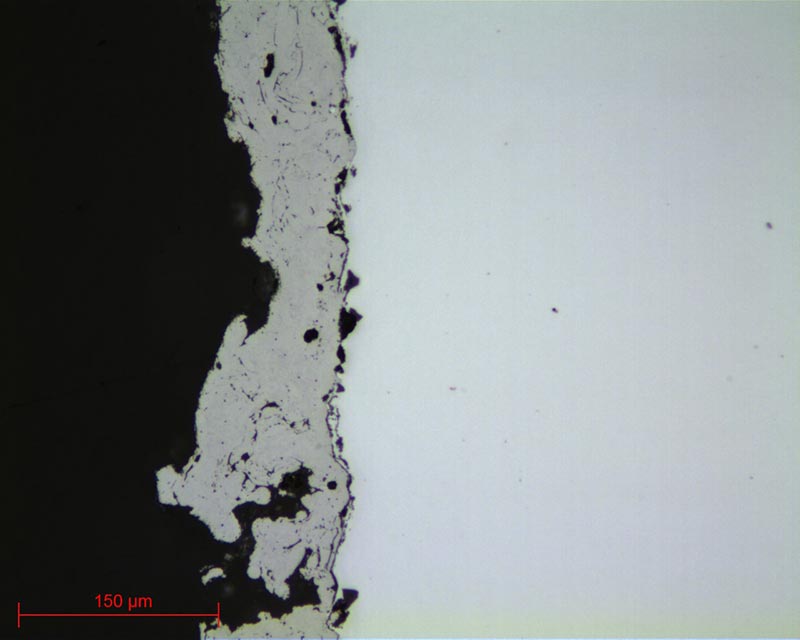

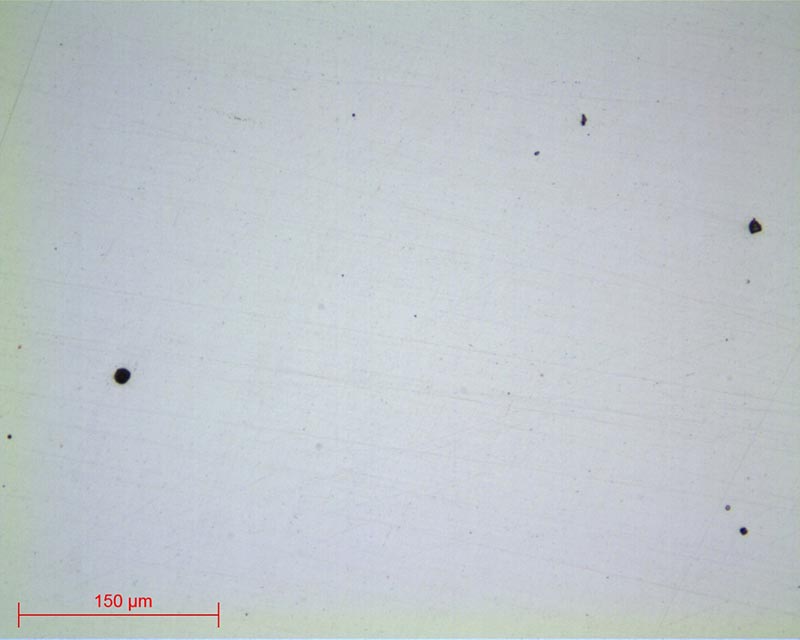

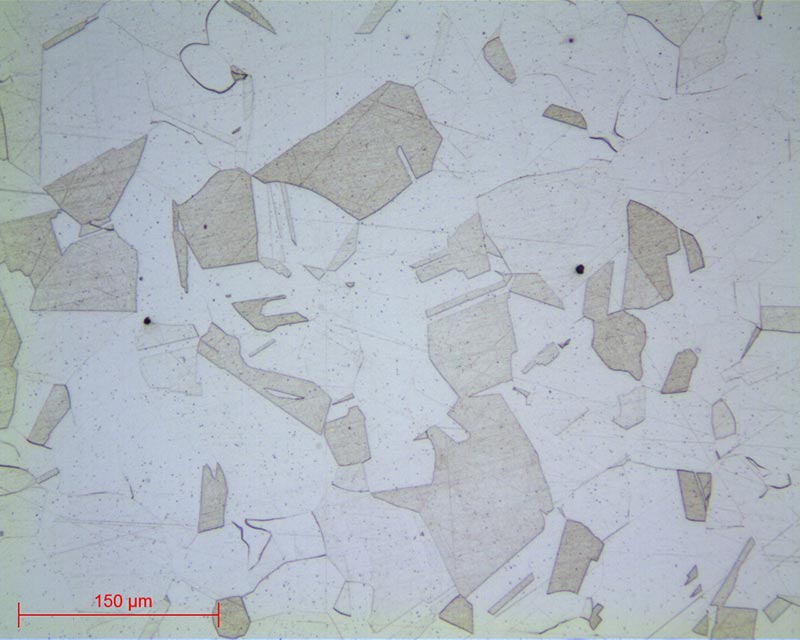

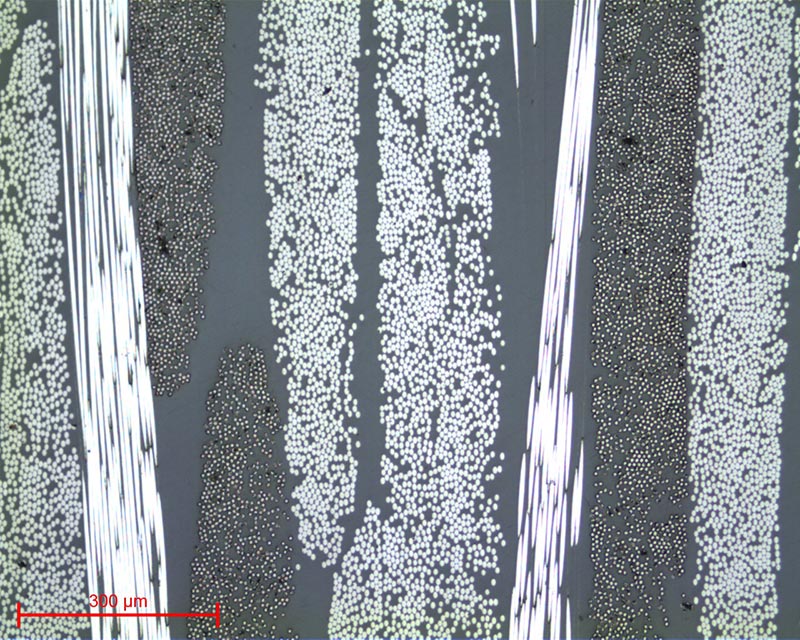

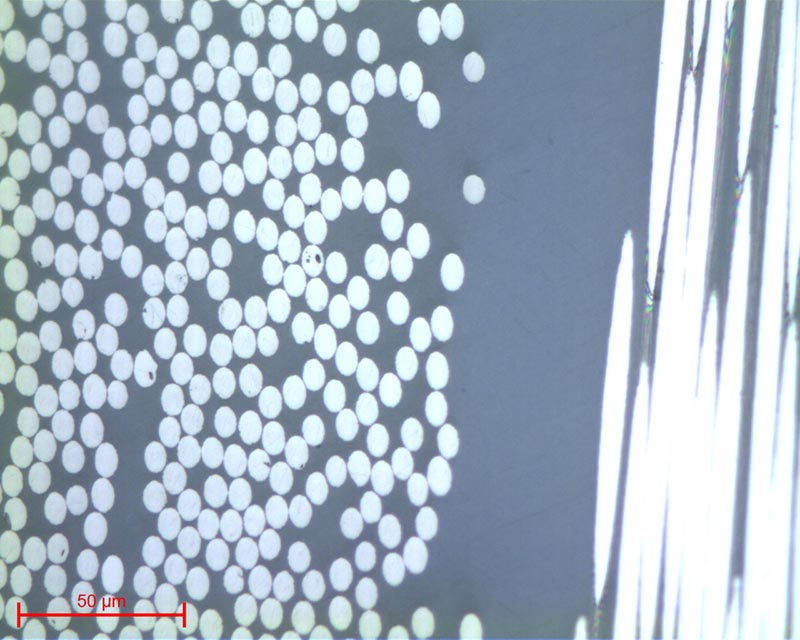

• Characterisation of the sample: revealing the microstructure of the sample by an etching reagent (if necessary) called “METALLOGRAPHIC ETCHING” and microscopic observation (optical or electronic).

CUTTING

In other words, it is essential to avoid heating or any deformation of the metal that could lead to degradation of the material. Cutting is a fundamental step which conditions the further preparation and inspection of parts.

=> Clamping, i.e. holding the workpiece, is also essential. Indeed, if the workpiece is not well held, the cut can present risks for the consumable, the workpiece and the machine.

CONSUMABLES

|

Stainless steel |

Titanium | Cobalt Chrome |

Ceramics | Polymers |

| Micro-cutting | UTW S Ø180 AO AOF II |

UTW S Ø180 MNF |

UTW S Ø180 CBN |

LM / LM+ LR |

UTW S Ø180 MNF LM+ LR |

| Medium-capacity cutting | A AO AOF II |

T MNF F |

S CBN |

LM / LM+ LR |

MNF LM+ LR |

| High-capacity cutting | A AO |

T MNF |

S CBN |

LM / LM+ LR |

MNF LM+ LR |

Table1: Choosing the right cut-off wheel type

MOUTING

=> Achieving good-quality mounting is essential to protect fragile materials and also to achieve good preparation results for polishing and future analysis.

Before mounting, the specimen should be deburred with coarse abrasive paper, for example, to re- move any cutting burrs. Cleaning with ethanol (in an ultrasonic tank for even greater efficiency) is also possible. This allows the resin to adhere as well as possible to the sample and thus limits shrinkage (space between the resin and the sample).

If shrinkage persists, it can lead to problems during polishing. Abrasive grains may become lodged in this space and then be released at a later stage, thus creating a risk of pollution for the sample and the polishing surface. In this case, cleaning with an ultrasonic cleaner between each step is recommended.

There are two mounting options:

• HOT MOUNTING is to be preferred for edge inspection purposes or if the metallographic preparation is carried out in preparation for hardness testing. This option requires a hot-mounting machine.

• The Mecapress 3 is a fully automatic hot mounting press.

• It is easy to use, its memory, process adjustment and speed of execution make it a high-precision machine.

• The hot-mounting machine has 6 different mould diameters from 25.4-50mm.

+ POINT

• If the parts to be examined are fragile/sensitive to pressure

• If they have a complex geometry such as a honeycomb structure.

• If a large number of parts are to be mounted in series.

The cold process can be used with:

+ POINT

+ POINT

CONSUMABLES

|

Stainless steel |

Titanium | Cobalt Chrome |

Ceramics | Polymers |

| Hot process | Hot epoxy Phenolic Acrylic Allylic |

Hot epoxy Phenolic Allylic |

Hot epoxy Phenolic Allylic |

Ø | Ø |

| Cold process | KM-U KM-B IP / IP-FAST 2S* |

KM-U KM-B IP / IP-FAST 2S* |

KM-U KM-B IP / IP-FAST 2S* |

KM-U KM-B IP / IP-FAST |

KM-U KM-B IP / IP-FAST MA2+ |

Table 2: Choosing the right mounting resin type

* Suitable for very large series

It is therefore not recommended to perform a hot mounting process with this type of material.

POLISHING

PRESI offers a wide range of manual and automatic polishing machines, with a wide choice of accessories, to cover all needs, from pre-polishing to super-finishing and polishing of single or series samples.

The MECATECH range of automatic polishers allows both manual and automatic polishing. With its advanced technologies, motor power from 750-1500 W, all the PRESI experience is concentrated in this very complete range. Whatever the sample number or size, MECATECH guarantees optimal polishing.

CONSUMABLES AND POLISHING RANGE

All the first steps of each range are called “levelling” and consist of removing material quickly to level the surface of the sample (and resin). Those given below are standard and can therefore be modified as required.

Applied pressures vary according to sample size, but in general the following applies: 1daN per 10mm mounting diameter for the pre-polishing steps (ex: Ø40mm = 4 daN) then reduce force by 0.5daN at each polishing step with an abrasive suspension.

| Range | N°1 | N°2 | N°3 | N°4 |

| Materials | Stainless steel; Cobalt-Chrome |

Titanium Cobalt-Chrome |

Ceramics | Polymers |

Table N°3: Choice of polishing range

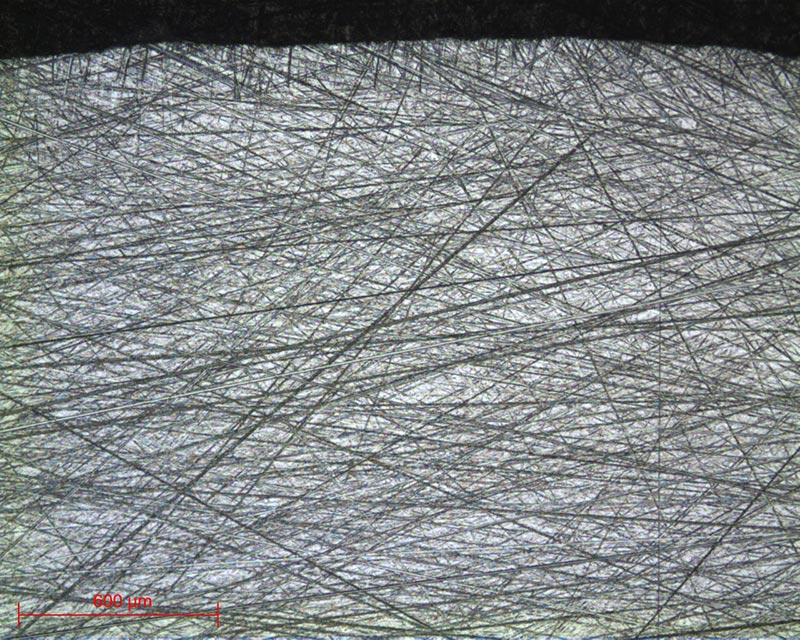

RANGE N°1

| N° | Support | Suspension / Lubricant |

Platen speed (RPM) |

Head speed (RPM) |

Rotation direction platen / head |

Time |

| 1 | SiC P320 | Ø / Water | 300 | 150 | 1’ | |

| 2 | TOP | 9μm LDP / Reflex Lub |

300 | 150 | 4’ | |

| 3 | RAM | 3μm LDP / Reflex Lub |

150 | 135 | 2’ | |

| 4 | NT | 1μm LDP / Reflex Lub |

150 | 135 | 1’ | |

| 5 | NT | Al2O3 n°3 / Water |

150 | 100 | 1’ |

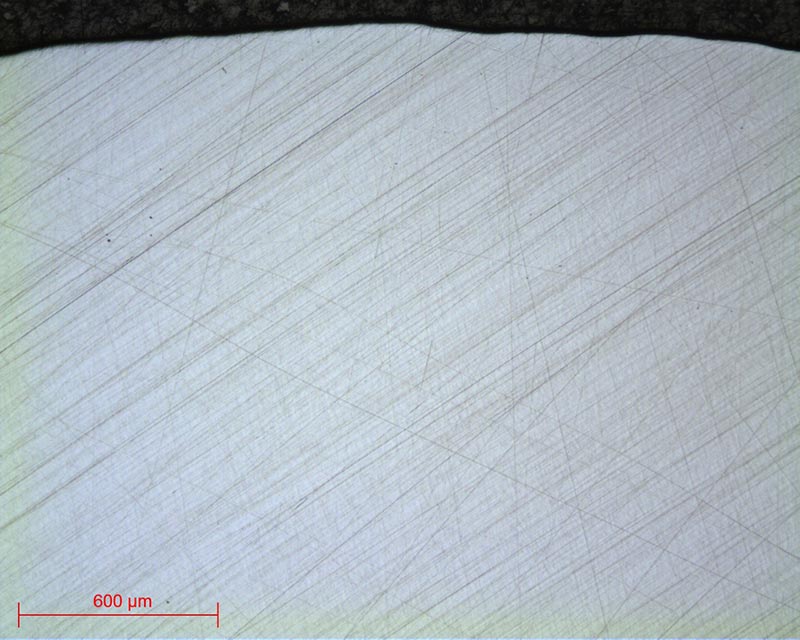

RANGE N°2

| N° | Support | Suspension / Lubricant |

Platen speed (RPM) |

Head speed (RPM) |

Rotation direction platen / head |

Time |

| 1 | SiC P320 | Ø / Water | 300 | 150 | 1’ | |

| 2 | TOP | 9μm LDP / Reflex Lub |

150 | 135 | 5’ | |

| 3 | SUPRA | SPM / Water | 150 | 100 | 5’ |

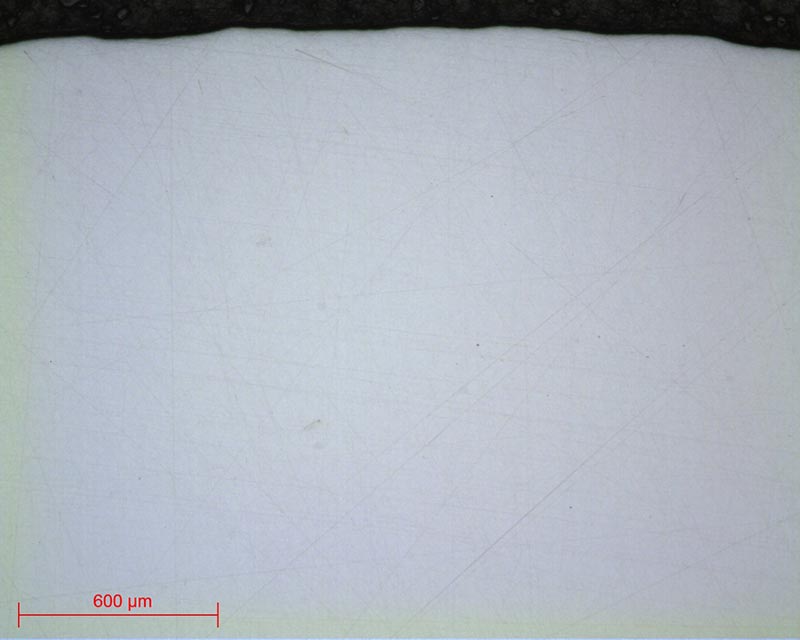

RANGE N°3

| N° | Support | Suspension / Lubricant |

Platen speed (RPM) |

Head speed (RPM) |

Rotation direction platen / head |

Time |

| 1 | Tissediam 40μm | Ø / Water | 300 | 150 | 2’ | |

| 2 | Tissediam 20μm | Ø / Water | 300 | 150 | 2’ | |

| 3 | TOP | 9μm LDP / Reflex Lub |

150 | 135 | 5’ | |

| 4 | NWF+ | 3μm LDP / Reflex Lub |

150 | 135 | 2’ | |

| 5 | SUPRA | SPM / Water | 150 | 100 | 2’ |

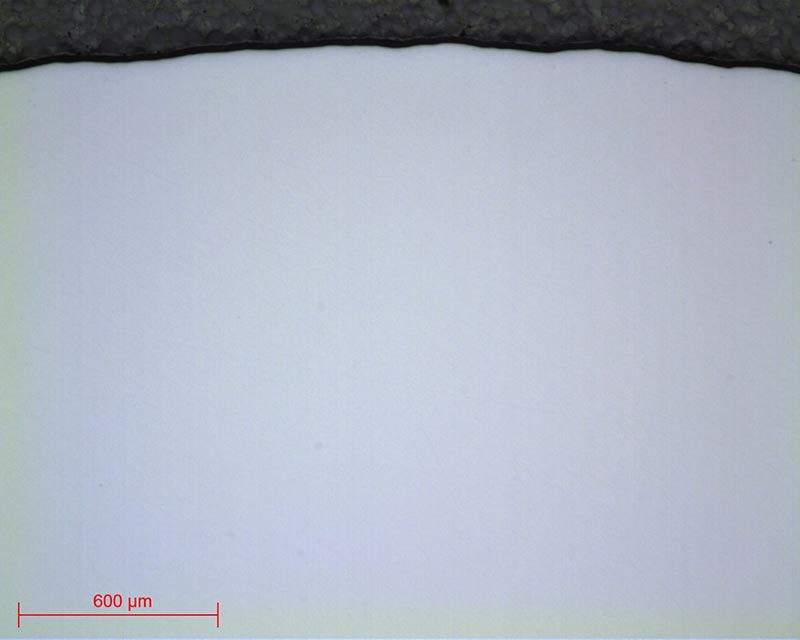

RANGE N°4

| N° | Support | Suspension / Lubricant |

Platen speed (RPM) |

Head speed (RPM) |

Rotation direction platen / head |

Time |

| 1 | Sic P320 | Ø / Water | 300 | 150 | 1’ | |

| 2 | Sic P1200 | Ø / Water | 300 | 150 | 1’ | |

| 3 | STA | 3μm LDP / Reflex Lub |

150 | 135 | 5’ | |

| 4 | NT | Al2O3 n°1 / Water |

150 | 100 | 1’ |

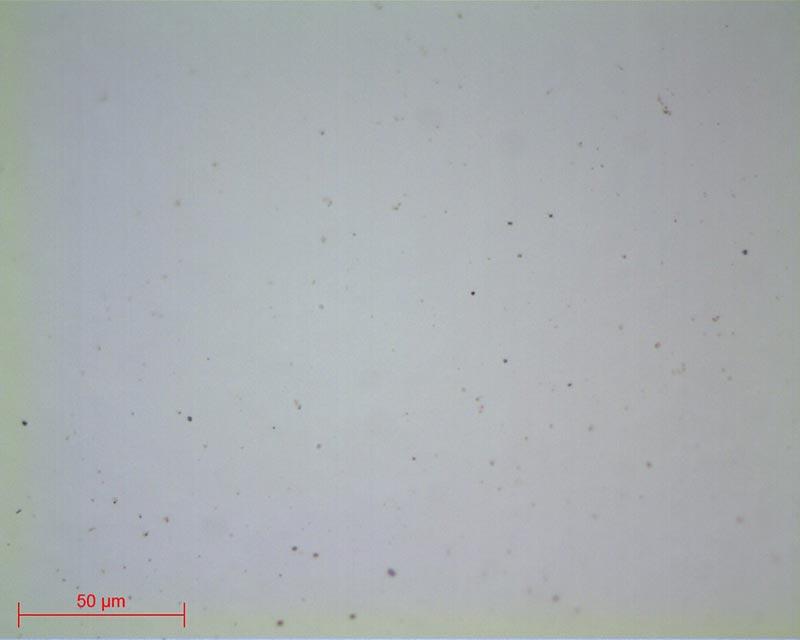

At the end of this preparation phase, the polished samples can be directly observed without metallographic etching. Otherwise, metallographic etching allows differences in relief and/or colour to be made between the different components and therefore allows them to be observed. It is mainly used on metals.

DOWNLOAD THE LAB'NOTE

Simply fill out the form below:

Discover our other Lab’Note:

- 3D printing quality control

- Hardened heat treatment control

- Medical device quality control

- Steel quality control

- Stainless steel quality control

- Cast iron quality control

- Copper alloy quality control

- Aluminum quality control

- Nickel quality control

- Titanium quality control

- Ceramic materials quality control

- Electronics quality control

- Precious metal quality control