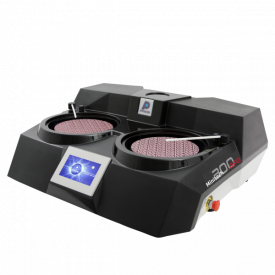

MINITECH 300 DP2

The MINITECH 300 DP2 is a manual polishing machine equipped with two platens Ø 250 to 300 mm and two motors. It has the most advanced technologies. Thanks to a motor power from 750W to 1500W, the entire PRESI experience is condensed in this most complete range on the market. User-friendly, reliable and robust, MINITECH provides a simple answer to all needs. With its affirmed style and edged lines, this new range is distinguished by its new design with an easily recognizable sleek and refined carbon look.

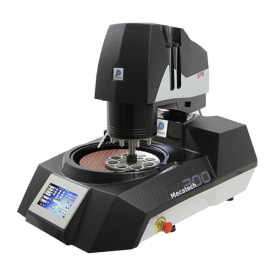

MECATECH 250 SPI

MECATECH 250 SPI is equipped with a Ø 200 to 250 mm platen / 4 pistons / individual pressure. It has the most advanced technologies. The MECATECH range allows both manual and automatic use. Thanks to a motor power from 750W to 1500W, the entire PRESI experience is condensed in this most complete range on the market. Whatever the size or the number of samples, MECATECH guarantees an optimal polishing. With its affirmed style and edged lines, this new range is distinguished by its new design with an easily recognizable sleek and refined carbon look.

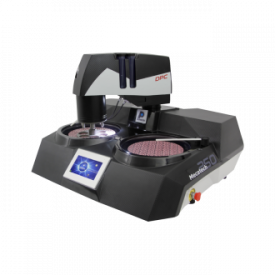

MECATECH 250 SPC

MECATECH 250 SPC is equipped with a Ø 200 to 250 mm platen / 6 pistons / individual and central pressure. It has the most advanced technologies. The MECATECH range allows both manual and automatic use. Thanks to a motor power from 750W to 1500W, the entire PRESI experience is condensed in this most complete range on the market. Whatever the size or the number of samples, MECATECH guarantees an optimal polishing. With its affirmed style and edged lines, this new range is distinguished by its new design with an easily recognizable sleek and refined carbon look.

MECATECH 300 SPC

MECATECH 300 SPC is equipped with a Ø 250 to 300 mm platen / 6 pistons / individual and central pressure. It has the most advanced technologies. The MECATECH range allows both manual and automatic use. Thanks to a motor power from 750W to 1500W, the entire PRESI experience is condensed in this most complete range on the market. Whatever the size or the number of samples, MECATECH guarantees an optimal polishing. With its affirmed style and edged lines, this new range is distinguished by its new design with an easily recognizable sleek and refined carbon look.

MECATECH 300 SPS

MECATECH 300 SPS is equipped with a Ø 250 to 300 mm platen / 8 pistons / individual and central pressure. It has the most advanced technologies. The MECATECH range allows both manual and automatic use. Thanks to a motor power from 750W to 1500W, the entire PRESI experience is condensed in this most complete range on the market. Whatever the size or the number of samples, MECATECH guarantees an optimal polishing. With its affirmed style and edged lines, this new range is distinguished by its new design with an easily recognizable sleek and refined carbon look. The sweeping movement of the MECATECH 300 SPS polishing head optimizes the use of consumables and improves samples flatness. This machine also improves productivity by increasing the capacity of the polishing head from 6 to 8 samples.

MECATECH 250 DPC

MECATECH 250 DPC is equipped with two platens Ø 200 to 250 mm platen / 6 pistons / individual and central pressure. It has the most advanced technologies. The MECATECH range allows both manual and automatic use. Thanks to a motor power from 750W to 1500W, the entire PRESI experience is condensed in this most complete range on the market. Whatever the size or the number of samples, MECATECH guarantees an optimal polishing. With its affirmed style and edged lines, this new range is distinguished by its new design with an easily recognizable sleek and refined carbon look.

MECATECH 334 SPC

Single station, automatic polishing machine. Equipped with a Ø 250 to 300mm platen, the MECATECH 334 SPC is a powerful and reliable polishing machine with the most advanced technologies for easy operation and easy maintenance. It gives the best polishing results on all types, sizes and number of samples.

VIBROTECH 300

The automatic vibration polishing machine. The VIBROTECH 300 is a vibrating polishing machine of Ø 305mm reliable and robust. Vibration polishing is an ultra-soft technique suitable for the super-finishing stages and particularly for the samples to be analysed

in EBSD (electron backscatter diffraction) or AFM (atomic force microscopy). This polishing method makes it possible to save inclusions and to eliminate surface hardening. Very easy to use, the frequency and amplitude of the vibrations can be modified in real time.

Le Cube

The ideal solution for basic polishing operations. LE CUBE is a Ø 200 and 250mm manual polishing machine. Simple, reliable and sturdy, it is the ideal solution for laboratories, schools or research centres. Equipped with a frequency inverter, LE CUBE has a high-torque motor turning either clockwise or counter-clockwise. The polishing plate is equipped with two speed rotation settings (150 & 300 RPM). The multi-jet water spray ensures the optimum lubrication of the platen surface. With its removable platen the cleaning of the machine is very easy. LE CUBE is dust free thanks to the clear integrated hood. LE CUBE direct transmission on bearings confers an incomparable silence in use. LE CUBE can be used with any type of polishing surface: non-adhesive, adhesive, PRESI Reflex System and magnetic. No particular adaptation is required.

Electer Evolution

Portable apparatus for mechanical grinding and polishing ‘in-situ”. The ELECTER EVOLUTION is ideal for preparation of surfaces before chemical etching or polishing and electrolytic etching. • Strong case for transport.

• Control panel.

• Electronic speed control.

• 2 outlets for motor connection.

• Selection of rotation direction.

• Torque motor 1500 to 25000 RPM.

• Reducer 1/4 increasing the power by 4.

• Tool holder with 90° bevel gear.

• Voltage: 220 Volts.

• Built in accordance with EC standards.

Power supply

• Input 220 volts single phase 50 or 60 Hz.

• Adjustable output from 0 to 100 volts, with display of voltage.

• Direct current rectified by silicon diodes.

• Ammeter with 2 ranges, 0 to 10 and 0 to 20 Amp.

• Programmation managed by PLC with memorization of the polishing and etching ranges.

• 2 timers, polishing and etching.

• Rear output to electro-polishing unit and front connector for work with special clamp-type holder.

• Time delays for starting and electrolyte flow control.

• Built in accordance with EC standards.