MECATOME T205

The MECATOME T205 is a manual precision micro-cutting machine characterized by its robustness and compact design. With a large working space, it allows for cuts with the highest precision and to work on a wide range of materials, from the softest to the hardest. Its powerful motor makes it possible to work at high and constant torque over the entire speed range from 100 to 4000 RPM.

Option:

- Quick-release nut - Tool-less cut-off wheel change (ref. 51725)

MECATOME T305

Robust and flexible, the MECATOME T305 accepts Ø 250 & Ø 300 mm cut-off wheels.

Its rotation speeds range from 1000 to 4000 RPM, allowing the use of metal discs as well as resinoids. Its stainless steel vane table is compatible with all clamping systems on the market, and its plunge cutting motion makes it ideal for routine cutting.

MECATOME T335

Puissante et précise, la MECATOME T335 est une tronçonneuse automatique sur son axe logitudinal et manuelle sur son axe vertical. Ses vitesses de rotation allant de 1000 à 6000 RPM permettent d’utiliser des disques métalliques comme résinoïdes.

La MECATOME T335 offre le meilleur des deux mondes avec la possibilité de réaliser des coupes régulées ou impulsionnelles tout en conservant la facilité d’une coupe manuelle.

MECATOME T265

Robust, the MECATOME T265 accepts cutting discs of Ø250 & Ø300mm. Its rotation speeds ranged from 1300 to 4000 RPM allow the use of metallic blades as resinoids. Its L-shaped table allows quick clamping of parts either horizontally or vertically.

Options and accessories:

- Magnetic filter (ref. 51271)

- Quick-release nut - Tool-less cut-off wheel change (ref. 51272)

- SUCTION AND EXTRACTION - Mist extraction with fluid recovery (ref. 51273)

- Base cabinet for manual cutting machine (small model) (ref. 51275)

- Left quick clamping vice (ref. 51280)

- Right quick clamping vice (ref. 51281)

- Stainless steel v-type moving jaw for clamping vice 45mm height (ref. 51282)

- Special fragile samples «delrin» thermoplastic moving jaw for clamping vice 45mm height (ref. 51283)

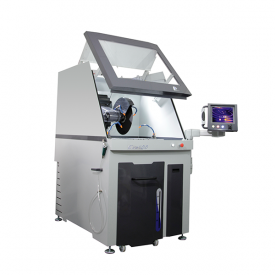

EVO 400

Large size cutting machine. Evo 400 Ref. 50400 / Evo 400+ Ref. 50430

The EVO 400 is a very spacious, large capacity machine. The height of the space under the grinding wheel measures 190mm. Its tables can bear the weight of parts over 200kg. This powerful machine, adapted for workshop use, combines ease of use with sturdiness. It has three cutting modes: assisted, automatic, programmable (ensures cut repeatability). Its ergonomic design, with a motorised hood and multilingual, coloured, touch screen simplifies the user-machine interface. Optional Extras:

• Positioning Laser.

• Manual transverse movement table (X axis) to assist with lateral adjustment of the simple, and enable parallel sectioning.

• Manual longitudinal movement table (Y axis) to increase cut capacity.

Diamond wire saw 3400

Fine cutting and absolute precision. With their stainless steel wire set with diamonds, the diamond wire saws cuts most materials. It is particularly recommended for cutting delicate samples such as silicon, glass or electronic components. Low speeds allow samples to be cut whilst protecting materials and preventing overheating. They ensure flat cut surfaces with clear edges, avoiding modifications to the structure on each side of the cut.

Diamond wire saw 3500 BASE

Fine cutting and absolute precision. With their stainless steel wire set with diamonds, the diamond wire saws cuts most materials. It is particularly recommended for cutting delicate samples such as silicon, glass or electronic components. Low speeds allow samples to be cut whilst protecting materials and preventing overheating. They ensure flat cut surfaces with clear edges, avoiding modifications to the structure on each side of the cut.