COPPER ALLOY

QUALITY CONTROL

INTRODUCTION

• Copper is a metal most often found in the form of rock combined with other elements (copper oxide or copper sulphide).

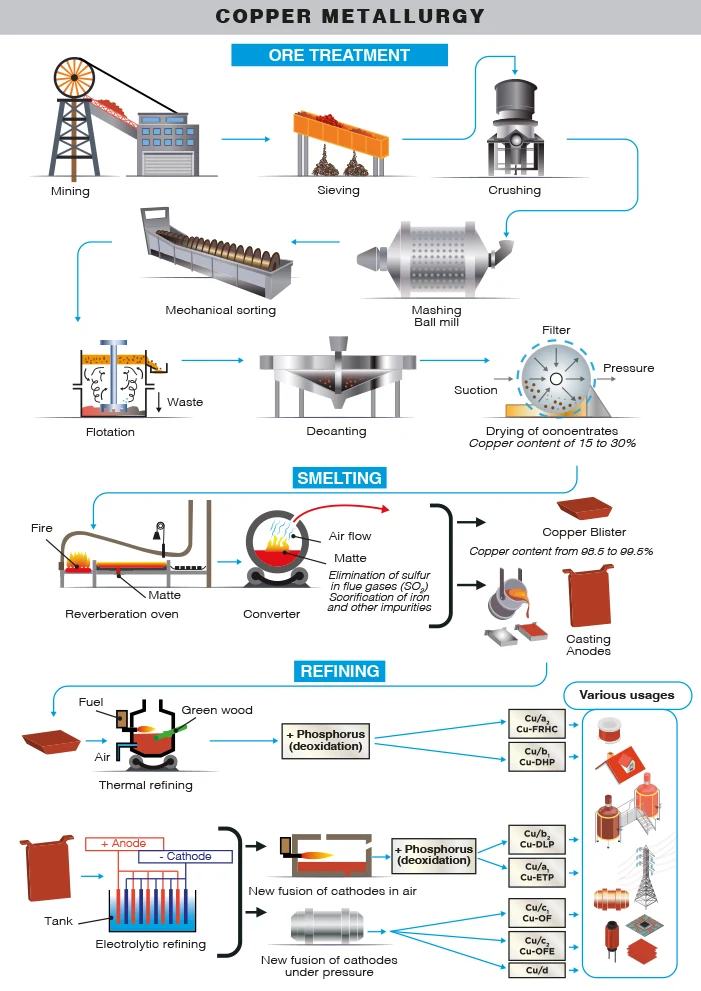

• A multi-stage metallurgical smelting process (Figure 1) produces pure copper.

• Low-alloyed copper also exists (4-5% alloy additions).

• Copper is a ductile material and is a good electrical and thermal conductor.

Fig. 1: Obtaining copper

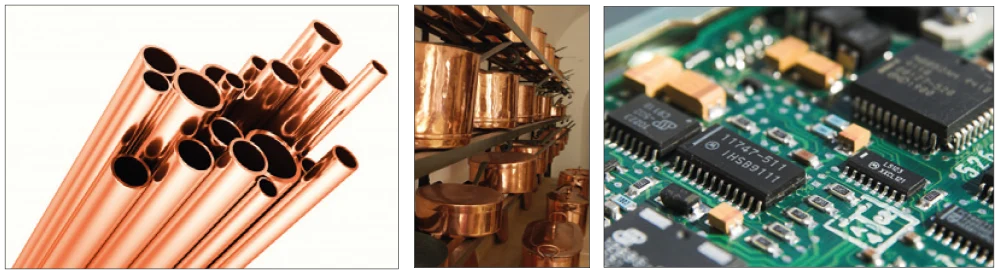

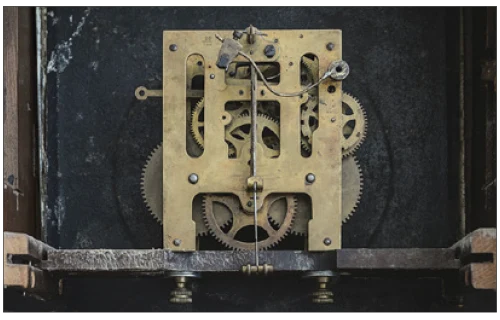

Brass is an alloy of copper and zinc whose percentage can range from 5-40 %. This addition of zinc makes this alloy more solid, making machining easier. This alloy can be used in the screw-cutting industry, in the manufacture of parts for jewellery or watches, etc.

Bronze is an alloy of copper and tin. The percentage of tin can be up to 20% depending on the manufacturing process. It can also have additional elements such as lead, which allows better machinability, or phosphorus, which improves mechanical characteristics.

Bronze is more resistant than copper alone, which is why it can be used as a friction material.

METALLOGRAPHIC PREPARATION

These operations come in this order:

• Standardisation of the geometry of the sample taken (if necessary), called «MOUNTING».

• Improvement of the surface condition of this sample, called «POLISHING».

• Sample characterisation: to reveal the microstructure of the sample by an etching reagent (if necessary) called «METALLOGRAPHIC ETCHING» and microscopic observation (optical or electronic).

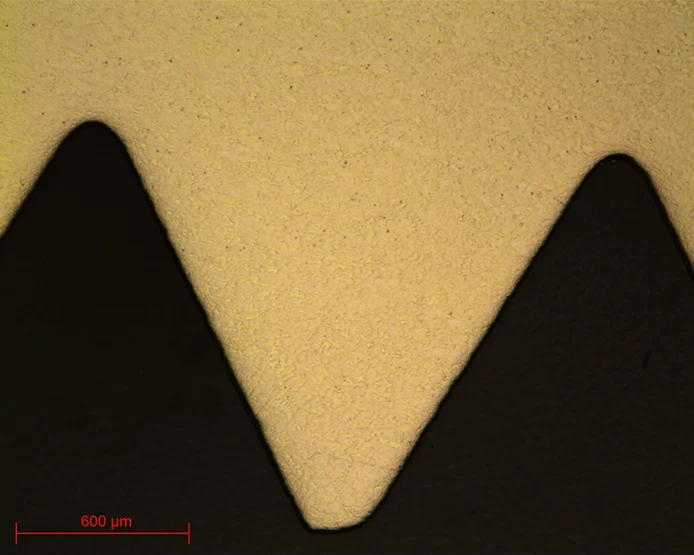

CUTTING

In other words, it is essential to avoid heating or any deformation of the metal that could lead to degradation of the material. Cutting is a fundamental step which conditions the further preparation and inspection of parts.

PRESI’s wide range of medium and large capacity cutting and micro-cutting machines can be adapted to any need with regard to cutting precision, sizing or quantity of products to be cut:

=> Clamping, i.e. holding the workpiece, is essential. If the workpiece is not held properly, the cut can be detrimental to the cut-off wheel, the workpiece and the machine.

CONSUMABLES

|

COPPER BRASS BRONZE |

| Micro-cutting | MNF UTW S (Ø180 mm) |

| Medium-capacity cutting | MNF |

| High-capacity cutting | MNF |

Table 1: Choosing the right cut-off wheel type

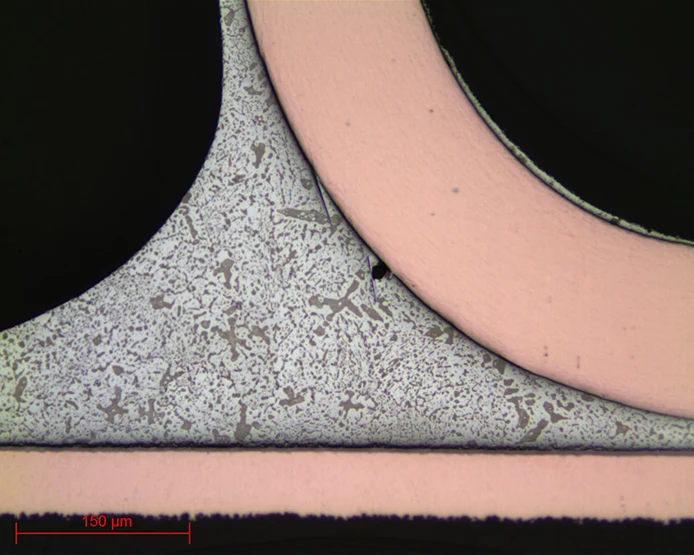

MOUNTING

=> Achieving good-quality mounting is essential to protect fragile materials and also to achieve good preparation results for polishing and future analysis.

Before mounting, the specimen should be deburred with coarse abrasive paper, for example, to remove any cutting burrs. Cleaning with ethanol (in an ultrasonic tank for even greater efficiency) is also possible. This allows the resin to adhere as well as possible to the sample and thus limits shrinkage (space between the resin and the sample).

If shrinkage persists, it can lead to problems during polishing. Abrasive grains may become lodged in this space and then be released at a later stage, thus creating a risk of pollution for the sample and the polishing surface. In this case, cleaning with an ultrasonic cleaner between each step is recommended.

There are two mounting options:

HOT MOUNTING

• Fully automatic hot-mounting press.

• Easy to use: memorisation, adjustment of processes and speed of execution make it a high-precision machine,

• The hot-mounting machine has 6 different mould diameters from 25.4-50mm.

+ POINT

COLD MOUNTING

• If the parts to be examined are fragile/sensitive to pressure

• If they have a complex geometry such as a honeycomb structure.

• If a large number of parts are to be mounted in series.

The cold process can be used with:

+ POINT

+ POINT

To meet user needs, PRESI offers a full range of cold mounting moulds:

The cold process has different mounting moulds with diameters from 20-50mm. These are divided into several types: optimised moulds called «KM2.0», rubber, Teflon or polyethylene moulds.

Cold mounting is also more flexible, hence the existence of rectangular moulds for more specific needs.

CONSUMABLES

|

COPPER BRASS BRONZE |

| Hot process | Phenolic Allylic |

| Cold process | KM-U 2S MA2+ |

Table 2: Choosing the right mounting resin type

POLISHING

PRESI offers a wide range of manual and automatic polishing machines, with a wide choice of accessories, to cover all needs, from pre-polishing to super-finishing and polishing of single or series samples.

User-friendly, reliable and robust, they provide a simple answer to all needs.

The MECATECH range of automatic polishers allows both manual and automatic polishing. With its advanced technologies, motor power from 750-1500 W, all the PRESI experience is concentrated in this very complete range. Whatever the sample number or size, MECATECH guarantees optimal polishing.

CONSUMABLES AND POLISHING RANGES

All the first steps of each range are called «levelling» and consist of removing material quickly to level the surface of the sample (and resin). Those given below are standard and can therefore be modified as required.

Applied pressures vary according to sample size, but in general the following applies: 1daN per 10mm mounting diameter for the pre-polishing steps (ex: Ø40mm = 4 daN) then reduce force by 0.5daN at each polishing step with an abrasive suspension.

The following is a general polishing range for copper and its alloys:

| N° | Support | Suspension / lubricant |

Platen speed (RPM) |

Head speed (RPM) |

Rotation direction platen / head |

Time |

| 1 | SiC P320 | Ø / Water | 300 | 150 | 1’ | |

| 2 | TOP | 9μm LDM / Reflex Lub |

150 | 135 | 4’ | |

| 3 | RAM | 3μm LDP / Reflex Lub |

150 | 135 | 3’ | |

| 4 | TFR | 1μm LDM / Reflex Lub |

150 | 135 | 1’ | |

| 5 | SUPRA | SPM / Water | 150 | 100 | 1’ |

For pre-polishing, the head and platen rotation direction should not be reversed, as this can detrimentally affect flatness. However, reversing rotation direction can help if a large amount of material has to be removed

The LDM suspension is used with the Reflex LUB lubricant, which allows the fabric to be sufficiently moistened without overloading it only with diamond suspension. In any case, care must be taken not to wet the fabric too much with suspension or lubricant, so as not to «aquaplane» with the fabric, which would make it ineffective.

During this stage, the rotation of the head is reversed in relation to the platen in order to keep the suspension on the polishing cloth as much as possible.

Depending on the result obtained, this stage can be replaced by the use of a PRESI n°2 alumina suspension.

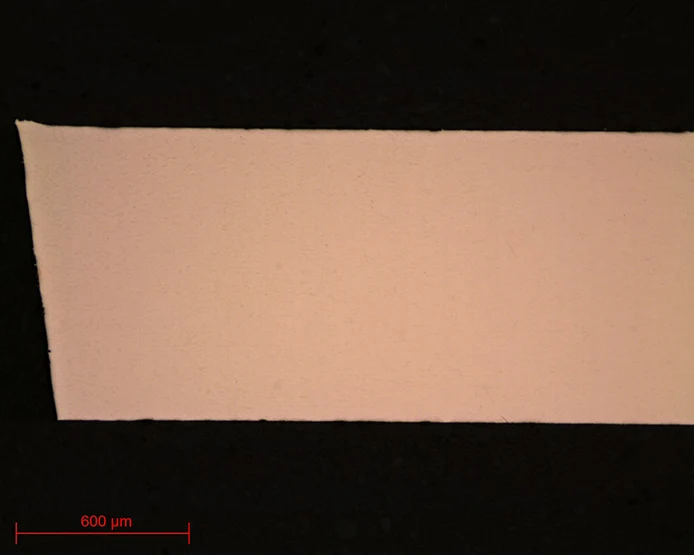

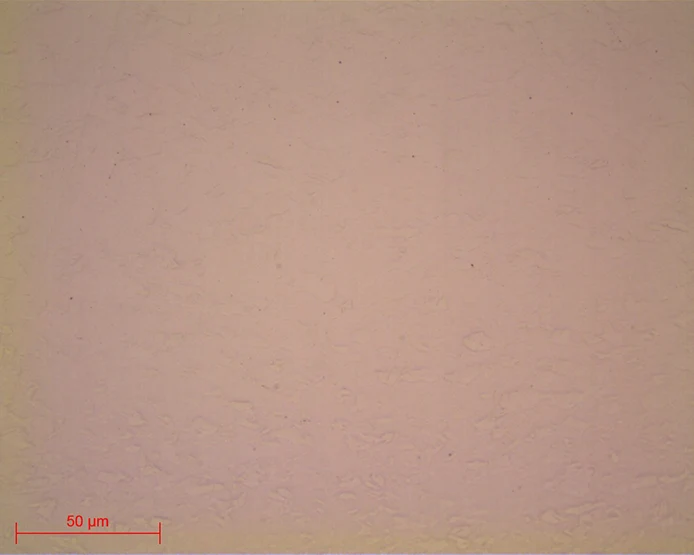

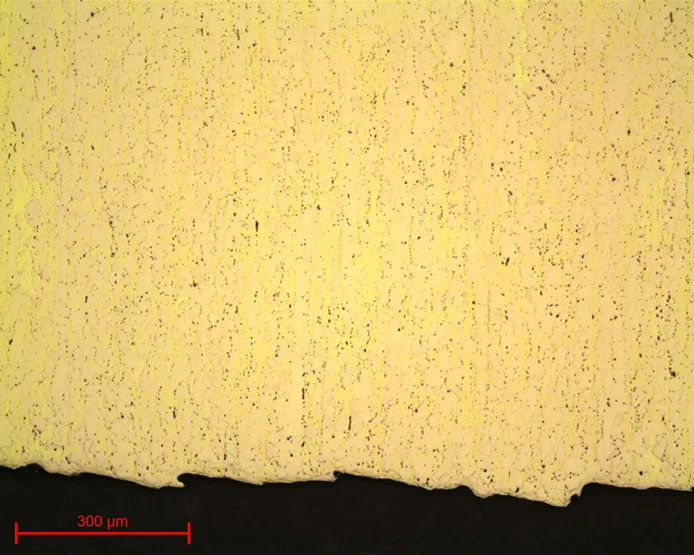

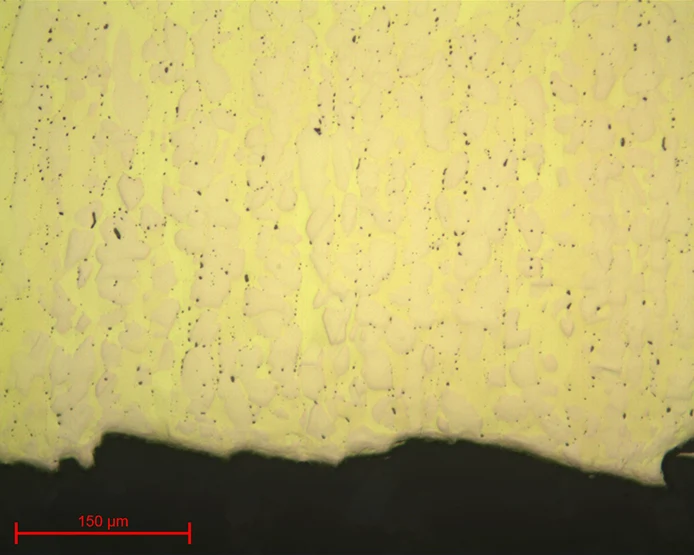

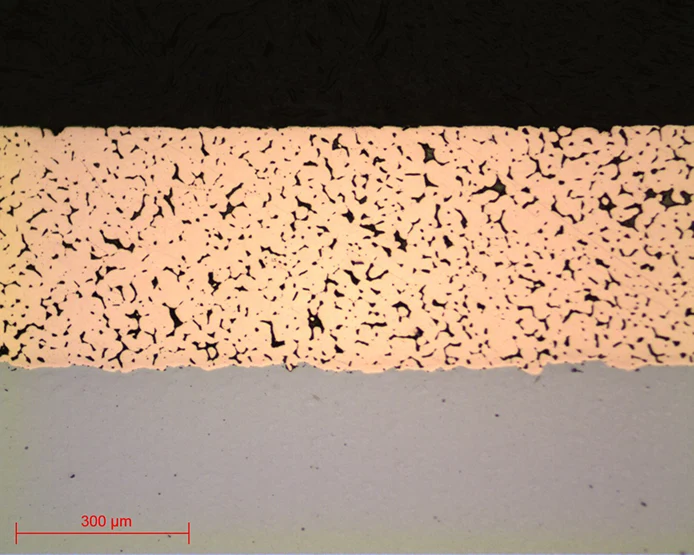

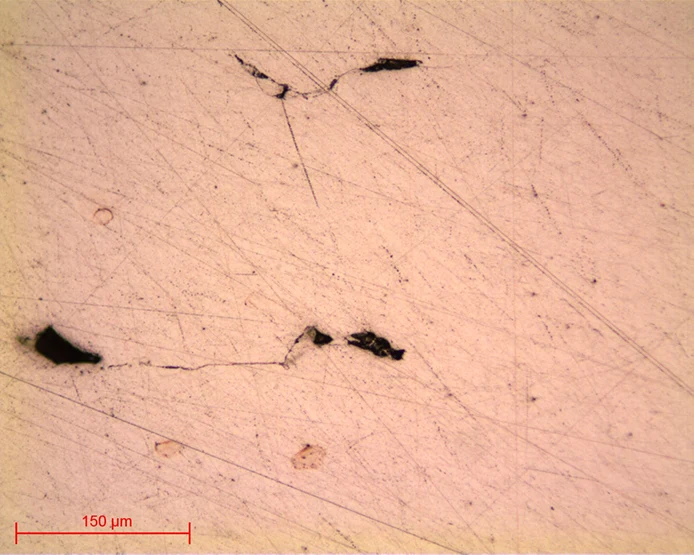

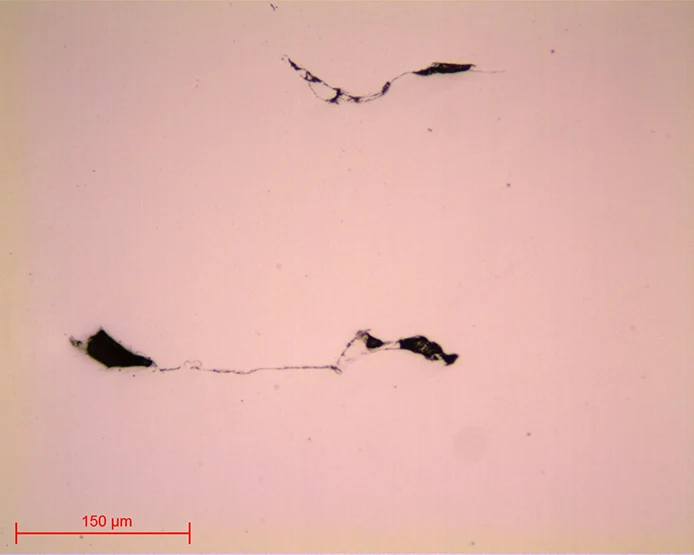

Figures 9-14 show the result on copper and brass after applying the above-mentioned polishing range.

Sometimes it is necessary to adapt the polishing range according to the sensitivity of the material. Below is an example of a range for a bronze coating with lead

| N° | Support | Suspension / lubricant |

Platen speed (RPM) |

Head speed (RPM) |

Rotation direction platen / head |

Time |

| 1 | SiC P320 | Ø / Water | 300 | 150 | 1’ | |

| 2 | SiC P1200 | Ø / Water | 300 | 150 | 1’ | |

| 3 | SiC P4000 | Ø / Water | 300 | 150 | 1’ | |

| 4 | NT | Alumina n°2 | 150 | 100 | 1’ | |

| 5 | NT | Alumina n°1 | 150 | 100 | 1’ |

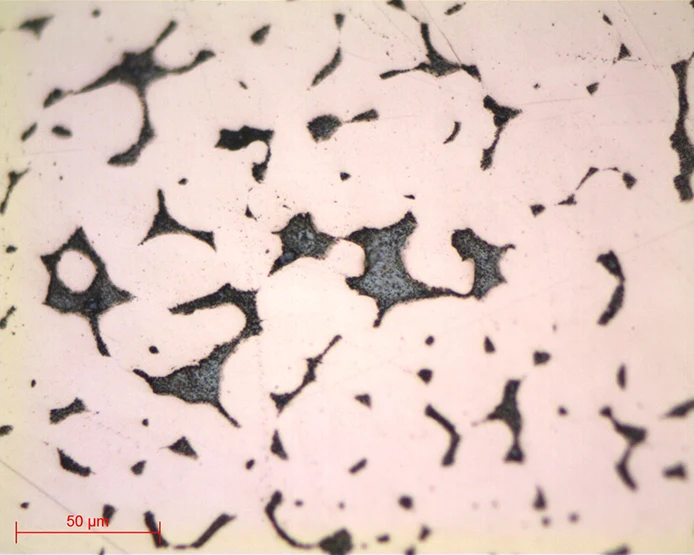

MICROSTRUCTURE

The use of etching reagents reveals grain boundaries, phases, etc…

The main reagents are:

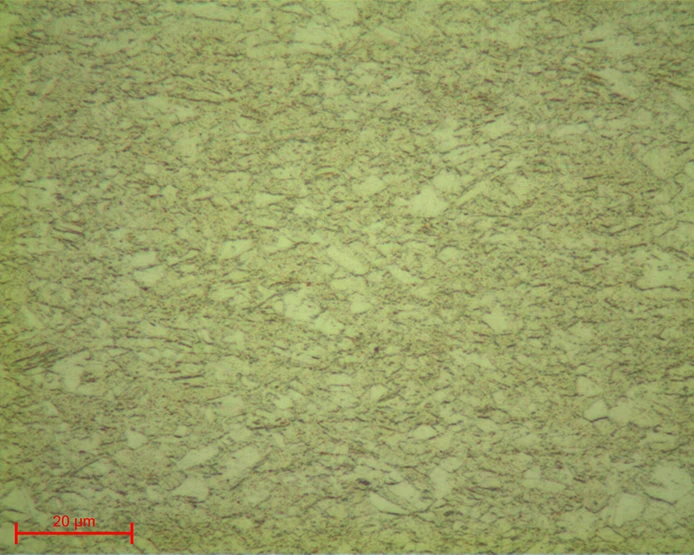

– alcoholic solution of Fe III acid chloride (figure 17)

– potassium dichromate (Figure 18)

These reagents are available in the PRESI catalogue and other specific reagents are available on request.

All of the micrographs presented were done using the PRESI VIEW software:

TO GO FURTHER

DOWNLOAD THE LAB'NOTE

Simply fill out the form below:

Discover our other Lab’Note:

- 3D printing quality control

- Hardened heat treatment control

- Medical device quality control

- Steel quality control

- Stainless steel quality control

- Cast iron quality control

- Copper alloy quality control

- Aluminum quality control

- Nickel quality control

- Titanium quality control

- Ceramic materials quality control

- Electronics quality control

- Precious metal quality control